The manufacturing of our KERA baby bed in solid ash or beech wood from sustainable forests, in compliance with all European guarantees, is a process that combines craftsmanship and environmental responsibility. Here are the key steps in this process:

Manufacturing stages

- Selection of sustainable wood : The first step is to choose wood from sustainably managed forests. This involves selecting wood certified by recognized organizations guaranteeing responsible logging and reforestation to maintain the health of the forest.

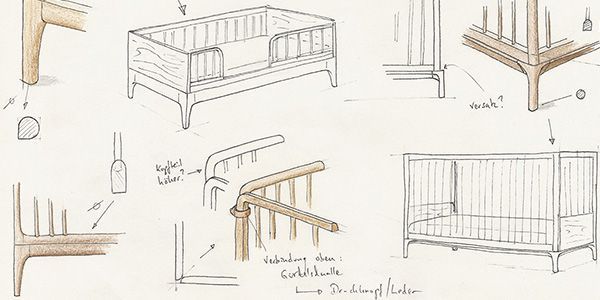

- Wood Cutting and Preparation : Selected wood is cut and prepared according to design specifications. This includes cutting boards and creating individual pieces such as the rungs, sides and base.

- Assembly : The parts are assembled in accordance with the design of the KERA evolving baby bed. High-quality assembly techniques are used to ensure the strength and safety of our baby bed.

- Finish : A non-toxic oil finish is applied to the wood to protect it and give it an attractive appearance. This finish must comply with European standards for the safety of baby products.

- Safety tests : Before the baby bed leaves the factory, it undergoes rigorous safety tests in accordance with European guarantees. This includes stability and resistance tests and verification of the absence of dangerous components.

- Packaging and labeling : The KERA convertible baby bed is carefully packaged and labeled. This includes providing clear instructions for assembly.

- After-Sales Service : Customer service and after-sales assistance are available to answer customer questions and concerns and ensure that the KERA baby bed is used safely and effectively.

- Recycling and Reuse : Reusing KERA baby cots is at the center of our DNA, contributing to sustainability and the circular economy.

Leave a comment